This time, we focus on what truly leads to innovation and improvements – the power of collaboration.

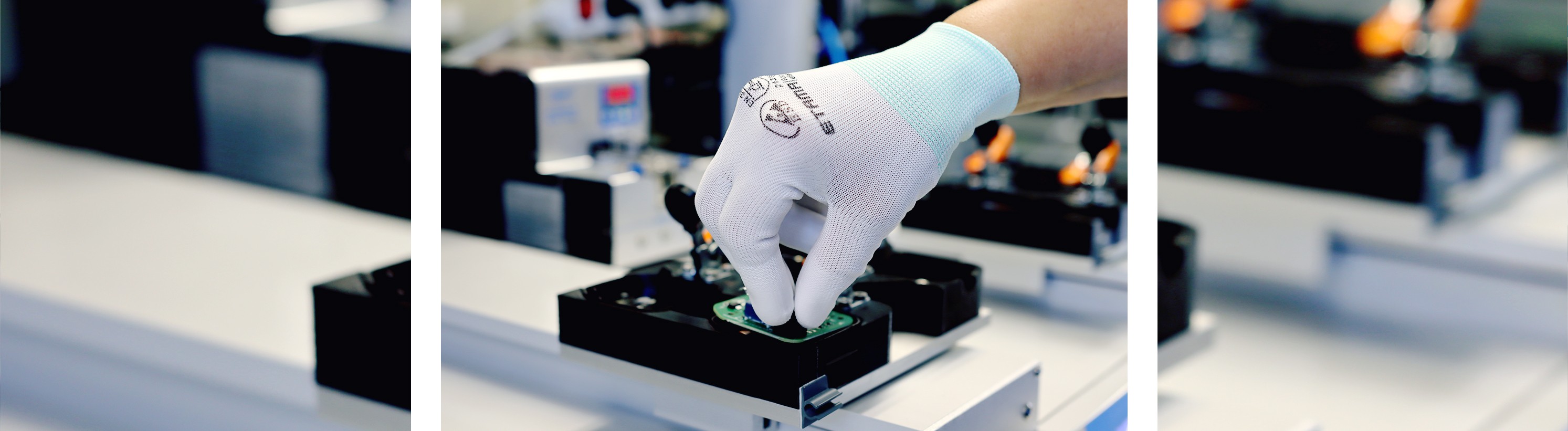

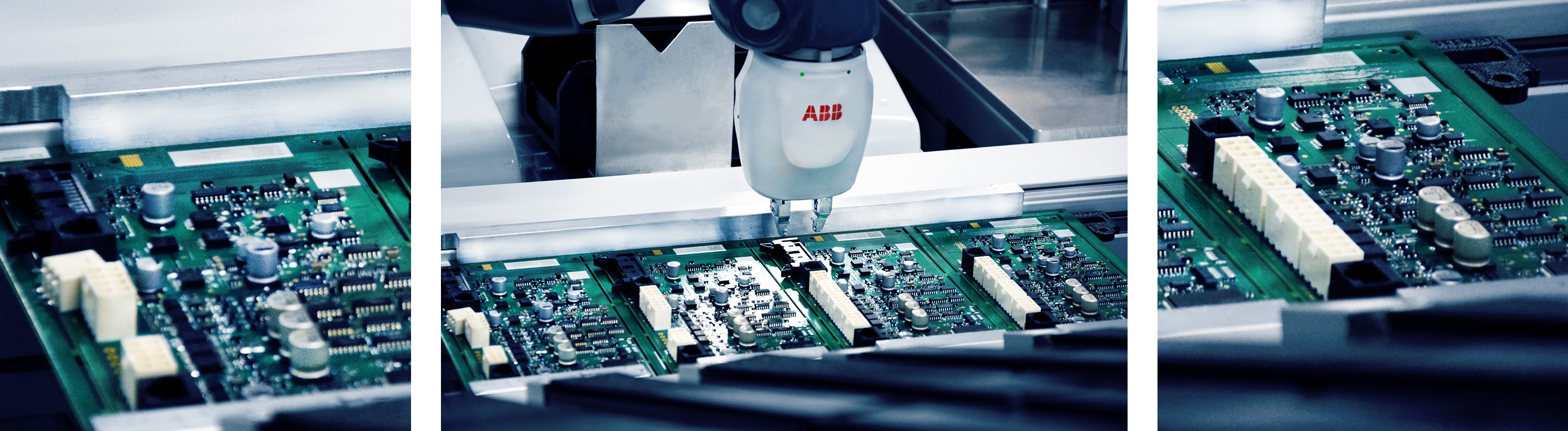

Behind every technology and process – there are people. At Kitron, we encourage internal collaboration possibilities for growth and the future of electronics. Recently, our Automation Engineers, together with other operators at Kitron Lithuania came up with an incredible result of developing the product housing screws assembly – a screwdriver robot, which eliminates manual work.

Assembly process change

The assembly process requires extreme attentiveness, quality, and efficiency. When it comes to product housing screws assembly, the operators were perfectly qualified for the manual process. “At first, we were a bit scared about the development because we were simply used to do it manually.” – shared Nijole Bubnienė, an Operator Mounting at Kitron Lithuania. “But our main aspiration is a comfortable workplace, which leads to higher quality and productivity. Sometimes you have to stand out of your comfort zone.”

The cooperation between the Automation team and other operators led to an incredible development example – the manual process of product housing screws assembly now is fully automatic, thanks to the new robot. The only thing an operator needs to do is place the products in the appropriate fixation (product holder) and press a button to begin the process. While the robot is doing the screw driving process, the operator can prepare for the upcoming operation. “We created all the improvements for ourselves, and now we are very happy about it. In fact, we are already planning some more improvements for the future. What was very important in reaching this goal? The communication with Automation Engineers. They were very attentive and cared a lot about the convenience of our work.” – said Nijolė Bubnienė.

.png)

.png)

.png)

The essential part of the success

When the new robot arrived, the operators took the initiative to gather themselves to communicate, learn how the device will be installed, and use it. Since they already have a similar robot, quite a few work-related questions have surfaced, such as: will it work the same way, can they sit while working, how to insert and remove the items, how will it detect any falses. The attention and curiosity were very high and fascinating.

So, what was the most critical part of the success? The willingness and determination of the team. The operators took the initiative to test the robot. After the testing, each operator spoke about what was convenient versus what was not. Since they work a lot of the time with the products, they mentioned the risks that can arise during the assembly process and the disadvantages of working with the manual method. The Automation team collected this information and redesigned the new robot based on the observations. Then, they replaced the original fixtures with a new clamping mechanism. The solution met the highest expectations. Also, the new robot was put in the most comfortable position for them in the workplace.

The operators have contributed to the development, resulting in a more stable and comfortable version of the process. That is why a continuous improvement in the production process is possible only when people feel free to express their ideas and, more importantly – they see it becoming a reality.

Summary

The bottom line of this success story is the importance of communication between operators, engineers, and other people, who work together. Therefore, we at Kitron support both individuals as well as the teams. We encourage employees to step outside their comfort zone, share their ideas and opinions. This is the attitude that we believe leads to growth and innovation.