Recently, Artificial Intelligence (AI) and machine learning has been introduced to aid and assist optical inspection. It ensures that every component is placed in the correct position and complies with the highest standards in the EMS industry. The AOI final control device is like an assistant who helps in precisely inspecting products. Now, there is something new to demonstrate in the AOI device and the inspection process.

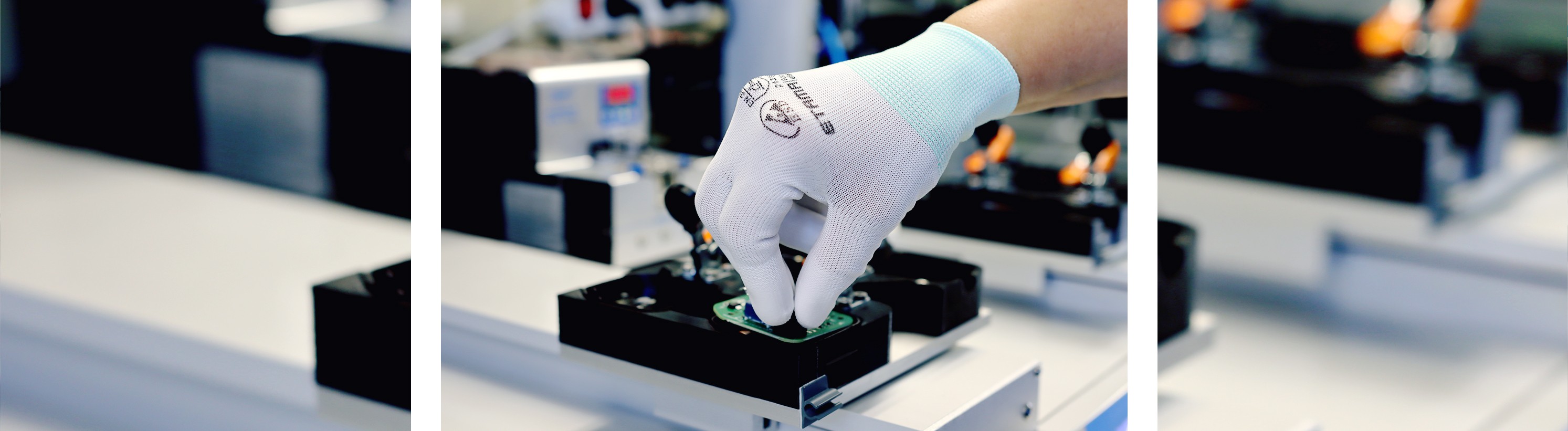

In order to ensure the highest quality, accuracy, and traceability of the components, after solving numerous application challenges, the Automation team of Kitron Lithuania has come up with a great solution.

A new perspective of optical inspection - artificial intelligence

With the market now having extremely high production demands, and with products getting more and more complex, manual inspection is no longer the most effective option.

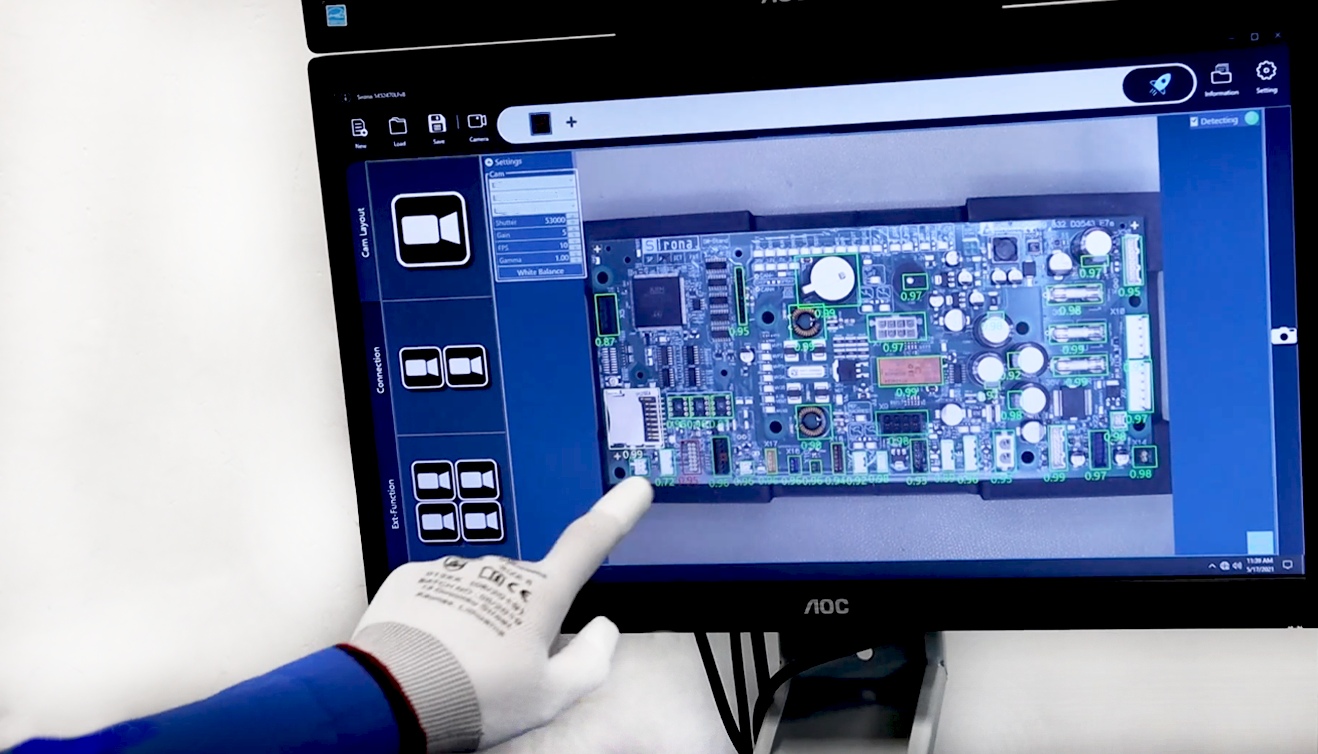

The new AOI final control device, recently developed at Kitron Lithuania uses machine learning, which is a type of artificial intelligence. It allows to “tell” software applications like the new AOI system how to behave without having to program it in a traditional manner of writing the code manually.

The software is given both good and wrong examples of a product in the form of images. From that, it builds a model with a ruleset. The ruleset then allows the algorithm to understand where and what specifically to look for in a very efficient way and allows to remove the possibility of unnecessary interpretation for the algorithm.

Basically, it helps detect any errors faster and with much higher precision. The software also reduces the number of false positives and speeds up the integration of a new product much faster than other systems. The AOI device takes care of component presence & absence, component polarity in a product.

How does it work?

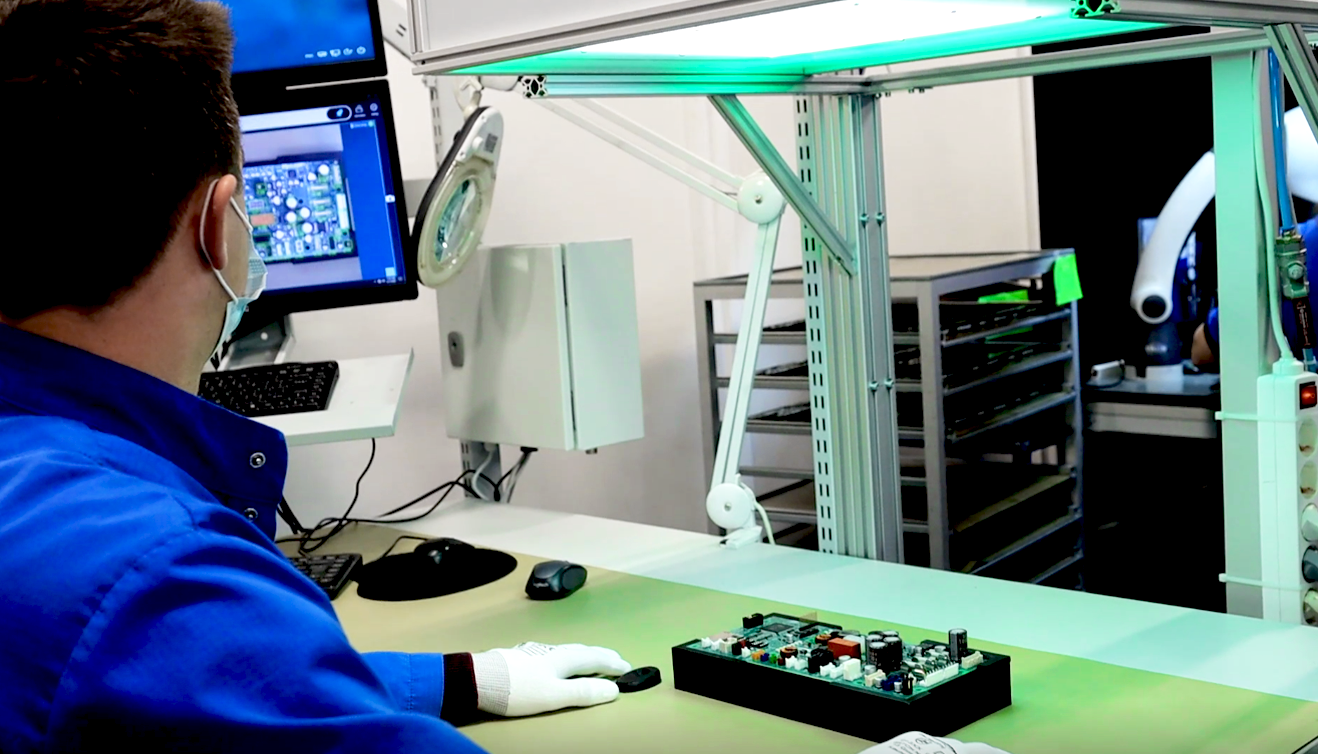

To reach top efficiency and acquire traceability, it is important to make it easier for operators to work, especially with many different components. For example, an operator places a product on the workspace, and it is immediately analyzed by the AOI system, if there is even a small change in any single component’s placement, for example, an incorrect component polarity, the system warns the operator with a red light and highlights where exactly the error was found.

In addition, traceability is easier than ever, because the system saves all the photos taken during the inspection process. The Automation team of Kitron Lithuania is planning to increase the inspection efficiency by up to 50 percent.

Furthermore, the use of the new automated optical inspection (AOI) device is extremely practical – it can be used in any other process, not necessarily final inspection. Mobility is another aspect correlating with higher efficiency.

Summary

Thanks to the effort of the Automation team of Kitron Lithuania, the new automated optical inspection (AOI) device with a machine learning algorithm ensures quality, accuracy, traceability, and improved inspection speed for our customers around the world. As industry 4.0 approaches, it is extremely important that we strongly consider the implementation of artificial intelligence to increase overall efficiency, quality and most importantly, adapt and evolve as the industry steps forward.