We at Kitron believe that the success of our electronics manufacturing relies on using the latest technology, which results in flexibility, efficiency, and, ultimately, the highest quality products for our customers. Managing our operations efficiently has been one of our top priorities. One of our services is providing traceability to our customers.

Through supply chain management, traceability is an essential competitive and strategic requirement in manufacturing. Regulatory industries require companies to track and trace goods from the raw material supplier to the customer, documenting all processes, stages, and changes along the way. There is no room for unreliable traceability.

Traceability is a requirement for many customers, who expect quality levels to meet the highest standards. In addition, manufacturers are also required to adhere to the industry's track and trace regulations.

Furthermore, traceability contributes to better customer relations. It offers the assurance that customers need in order to be satisfied.

How does it work?

The process of tracing begins when we mark parts directly with unique identifiers or other information. We are able to mark all unique units/packages with coded stickers. For instance, traceability can already be initiated during the registration of incoming material when package-by-package data is recorded for each delivery. In this way, we can capture all movements, receipts, shipments, and sequences during all stages of electronics production within the company. In addition, the traceability information in our business management system is constantly updated.

Then, each predefined component goes through a detailed quality check. Our system keeps track of components subject to this type of control.

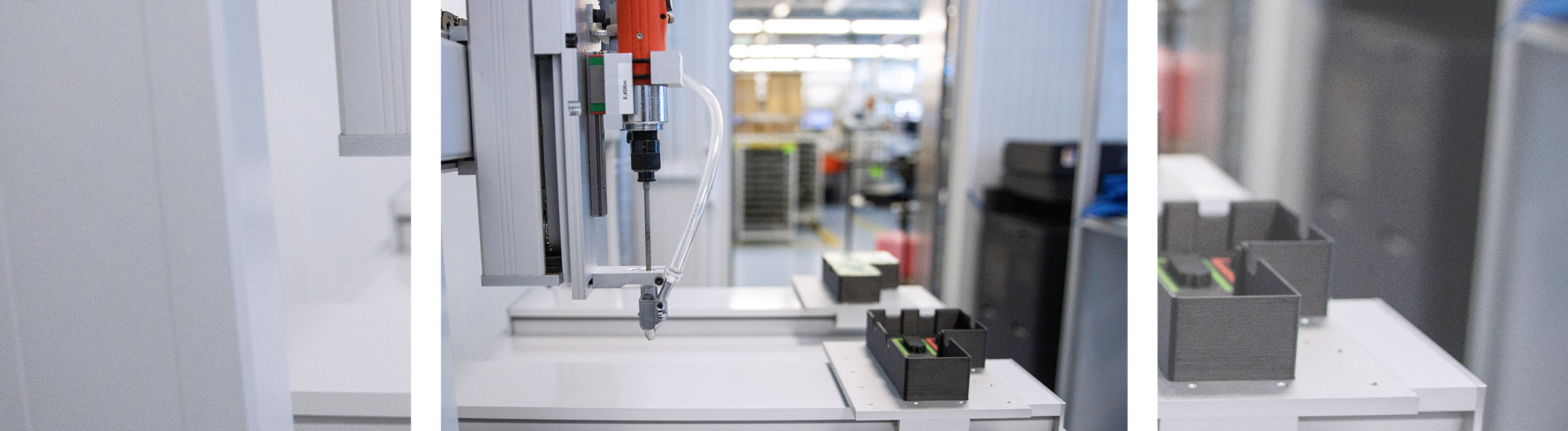

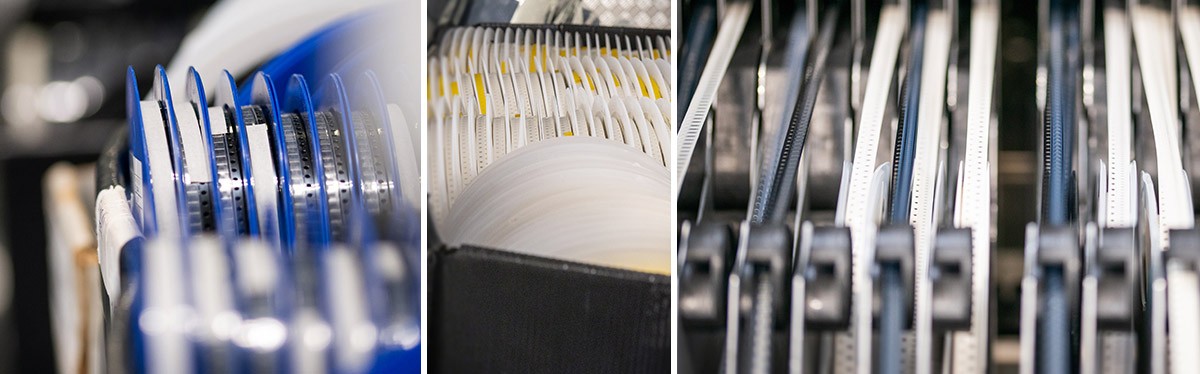

Upon completion of the goods-in process, SMD components are stored in automated storage, and the rest are in other locations. The components are released to production based on the generated pick list from the system, which indicates the quantities of material needed for production along with the pickup location.

Our traceability service includes not only records on all traced operations of the manufacturing route, starting from the PCB Laser marking step through all process operations like SMT, THT, AOI, Mechanical Assembly, Cleaning, Coating, Drying, Depaneling, Final Inspection, and so on, but also materials used records, product genealogy, the operators and machines and times a unit passed through, test results, quality data, repair history, and packaging records. All this data is available in comprehensive trace reports and serves as a unit’s device history record. Traceability allows us to identify the root cause of quality incidents when they occur.

Have you ever thought that it may be possible to get all of the information about the product from one single barcode? At Kitron, we are using a laser - a simple and effective way to have control of every product in the factory. Marking sensitive electronic components with lasers is the preferred method. Targeted energy input and stable laser properties provide process assurance - regardless of the type of component material.

The last step of production is quality control and product packaging. In the traceability process, all boxes are marked according to individual customer requirements and have Kitron’s internal traceability serial number.

Summary

As supply chains become more complex, the importance of traceability rapidly increases. At Kitron, we can offer traceability in our processes down to the smallest component. Considering that every situation requires a unique approach, our team is able to find the most appropriate traceability solution. Our customers benefit from this by avoiding potential errors, improving transparency, and ensuring the highest quality.