Our secret to precision - The Position Control Stand at Kitron Lithuania

We at Kitron continuously aim to improve the value for our customers. To do that, sometimes it is necessary to take some time and re-think our daily operations. Most of the time, it leads to some simple but effective ideas. This time, we would like to show how we strive for the highest quality of the manual screwdriver process. There's no magic in here – only technology and precision.

A simple secret to a responsible process

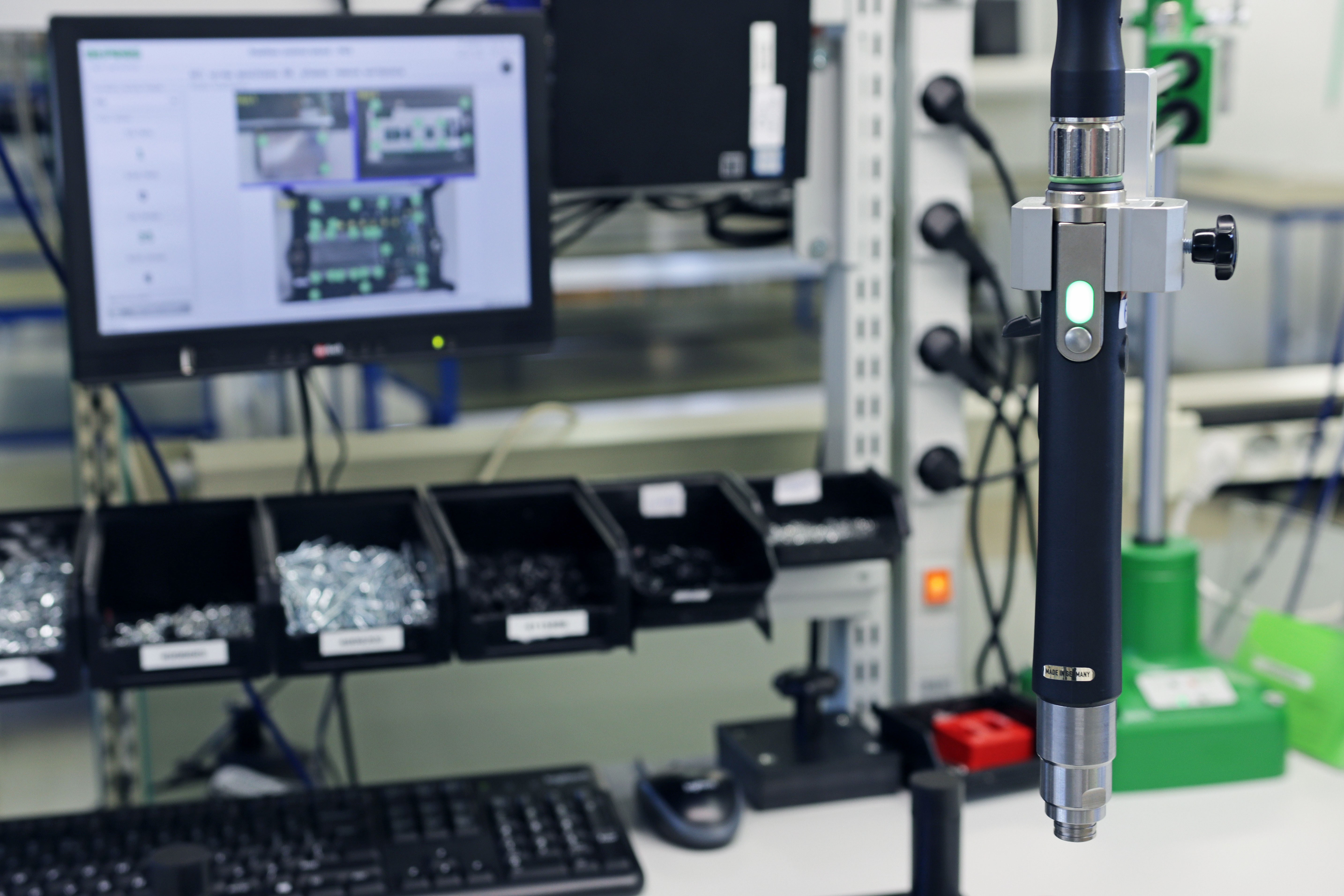

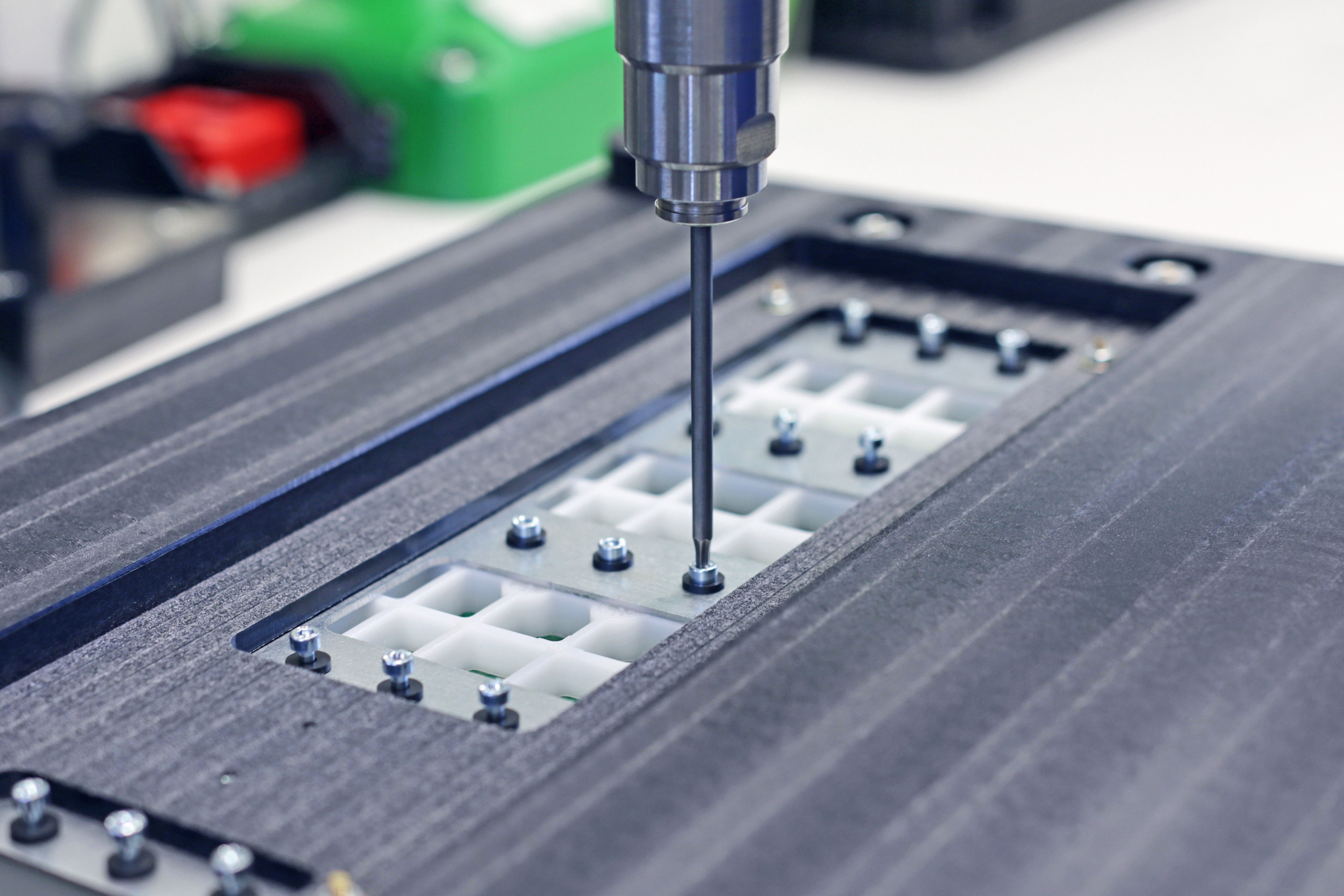

This time we bring The Position Control Stand (PCS) device to your attention. This device guides the screwdriver tool securely to the assembly position and reduces the operator's strain by absorbing the reaction torque. The PCS system ensures that the correct connection element is assembled to the exact torque at the right place and at the right time.

With these manual stations, the reliability of this process is guaranteed, regardless of personnel changes. This modern and innovative manual workstation is an ergonomic workplace for our employees and helps Kitron perform its best for the customer. It is possible to have it all – ease of use, the ability to ensure the highest quality, and the possibility to evaluate any possible mistakes.

The technology of precision – how it works

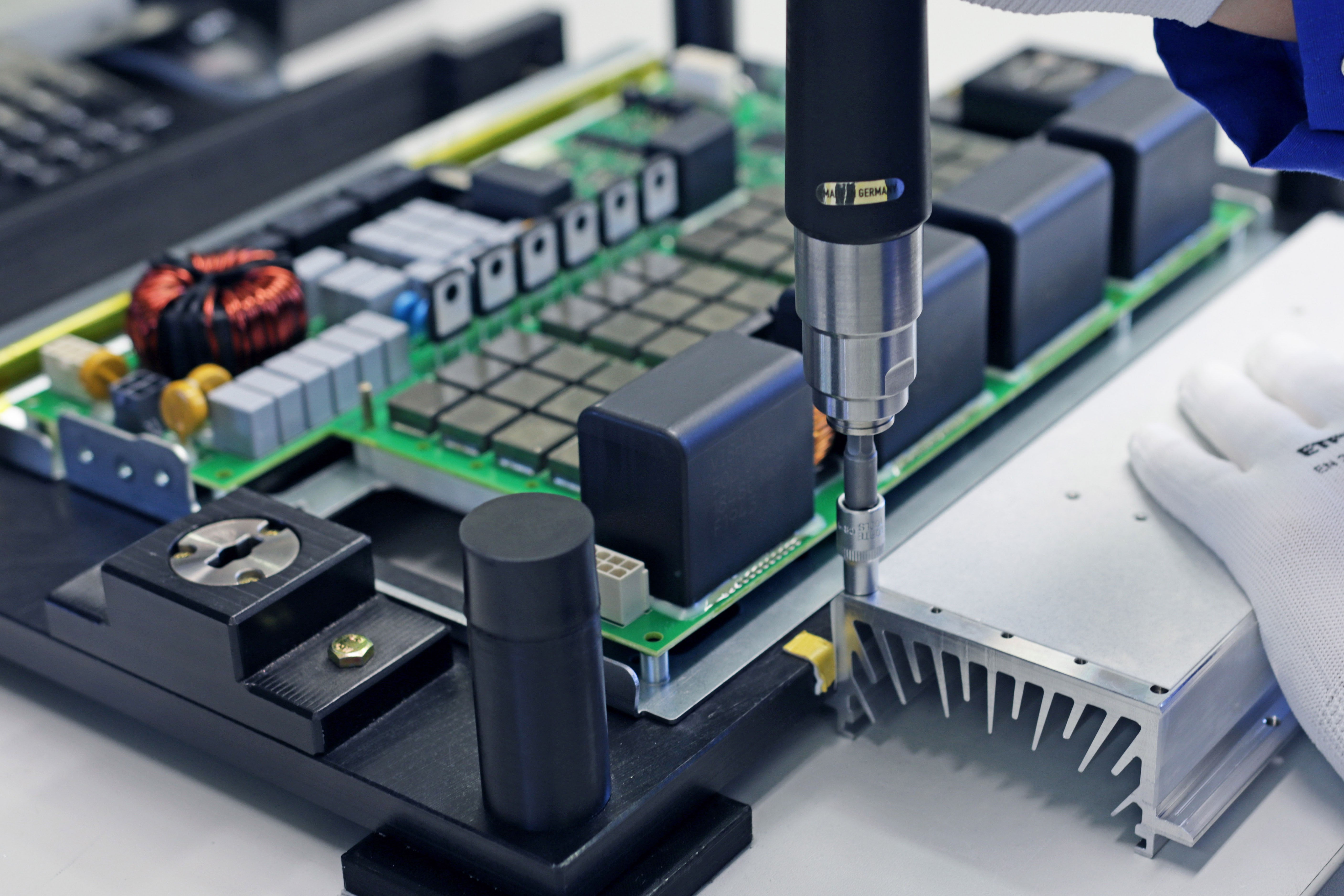

The position control stand coordinates, optimizes, and controls the whole production process. This system is operated with servo screwdrivers, which enable free programing of the screw tightening – torque, angle, speed, waiting time and rotational direction are adapted individually to the screwdriver task. An integrated torque and angle recording enable the exact control of the screw tightening and essential processing parameters documentation.

The position recognition feature increases processing reliability in applications where several screw positions need to be assembled in a particular order on one product – it may not seem important, but it actually is. The order needs to be accurate to ensure the best quality.

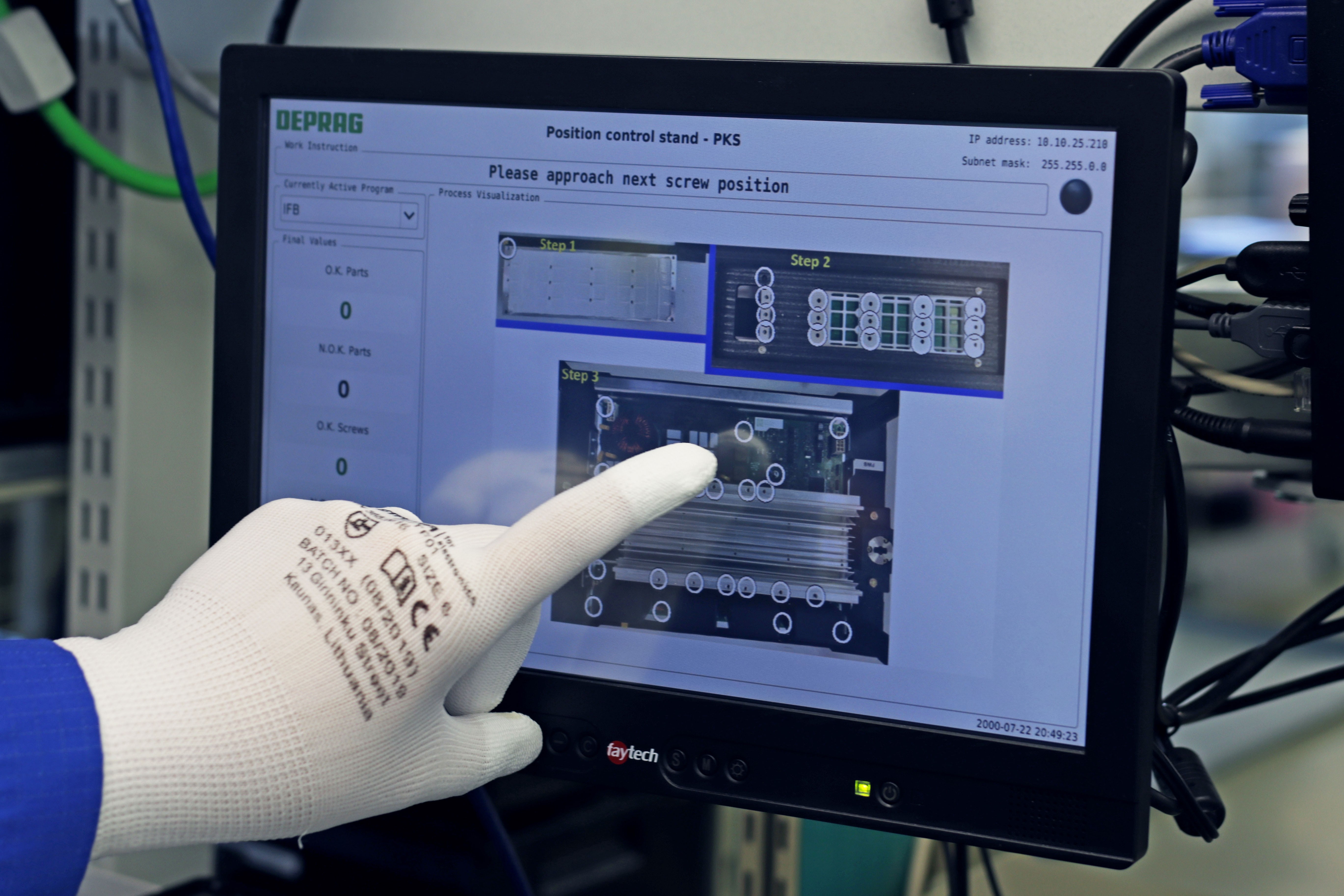

As soon as the position control stand is in the correct position, the screw tightening process begins. The stand is equipped with guidance hardware, and the software will only activate the right function once situated in the correct position – to avoid mistakes. The system is used to determine and monitor the relevant required operating mode and the order of positions. The screw can only be tightened if the operator has kept the order in the correct sequence. It is simply not possible to make a mistake here.

Another good thing about it is the Touch Monitor, which gives the operator the exact instructions and shows in color which positions on the product have already been assembled and marked on the screen with a text display "OK" or "NOT OK". The lit-up status LEDs on the base stand also inform the operator of the screw assembly's current status.

A better assembly quality in screwdriving process to our customers

Since Kitron Lithuania has integrated the system into its electromechanical assembly processes, it actually solved possible quality problems. The Position Control Stand (PCS) gives full process traceability and makes the workspace ergonomic like never before. A stable workflow sequence improved the assembly cycle's time and reduced mistakes to the lowest possible point – what could be better to offer our customers? Automatic torque control for screw tightening and screw position tracking improved quality and gives full traceability. So we can be sure that complex products are assembled without waste and additional cost. Quality is the top priority at Kitron and we continue delivering it to our customers!