Development and prototyping are probably the first two things, people familiar with 3D-printing, think of when mentioned. In the previous article, we focused on production use, but development is still a large utilization area. Over the last few years, we have used the principle of rapid prototyping in many projects, both large and small. This article will focus on developing new solutions with 3D-printing, some of the projects we have done, and the road from prototype to production.

The very start: rapid prototyping

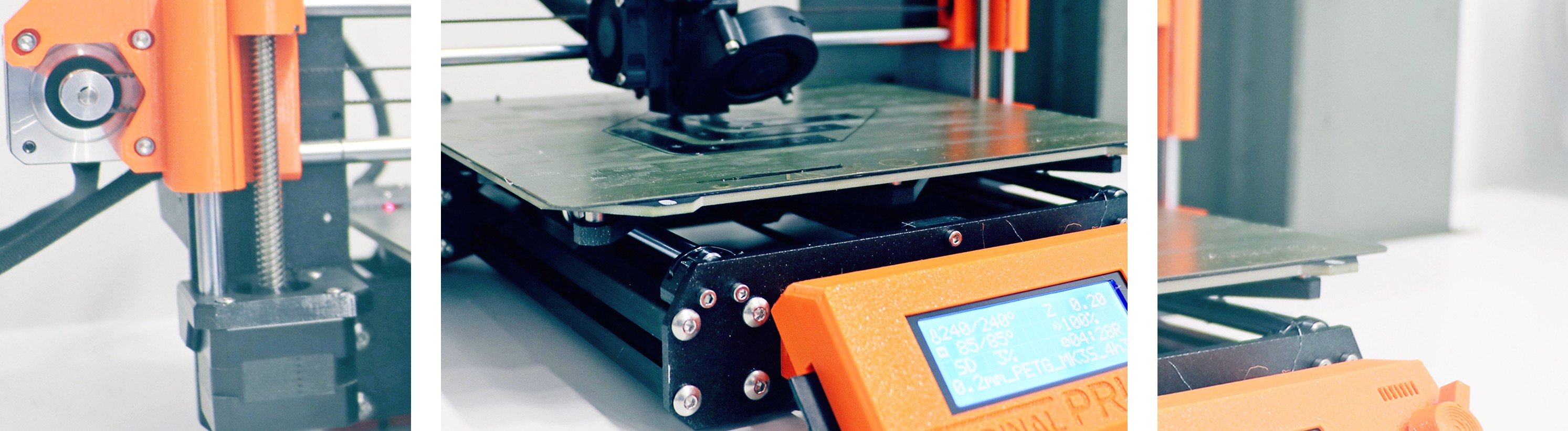

When doing any kind of development, it is very advantageous to test out ideas as quickly as possible. Before, 3D-printing was somewhat tricky because traditional methods of creating parts involve a lot of work and take substantial amounts of time. However, with 3D-printing, you simply upload a model, press print, and wait for a few hours. When the print finishes, the design can be physically analyzed.

If the design occurs with an error such as the wrong size or another broken property and cannot be assembled, a new one simply had to be print. Hopefully, the next one is as intended, and the design can be tested. A development workflow using interactions like these is called rapid prototyping and is widely used in our developer teams.

Whereas previously, it was necessary to do lots of design evaluations, make drawings and expect that the final parts will work as planned. This process could have potentially mean losing lots of money.

Now it is possible to just make a 3D CAD-model, print it, test it and if it does not work, you have wasted a near-zero amount of money. Not to consider all the time saved by not having to make and edit for technical drawings during the design process instead of once at the end when everything works. Also, the difference in costs lowers the threshold to move into physical tests. It makes it possible to test more ideas, giving better solutions.

.jpg) 3D-printed product fixture improves accuracy of positioning.

3D-printed product fixture improves accuracy of positioning.

Application in different projects

At this point, the rapid prototyping methodology is so ingrained into our engineers' minds that there are very few development projects in which additive manufacturing is not involved to some degree. Of course, the degree of utilization varies between projects and their targets. Still, in almost all of them, it can be used and brought with all its advantages.

Some examples of projects where 3D-printing was instrumental to the projects were; making a pressing machine with heating capabilities to mount heatsinks, a pneumatic robotic gripper to pick up PCBs and a master's thesis we had, where a 5-axis robot was made to inspect solder joints. In the two former cases, the project would probably never be attempted without 3D-printing. While the heatsink-press allowed the project to be completed in a very narrow timeframe.

The extent of use was different in the projects. For the pneumatic gripper, everything was 3D-printed in the first prototype except for the pneumatic components. Most of the structural components were printed in the solder inspection robot, barring some aluminum profiles and the moving parts. One cool feature to mention in the robot is that it had a fully functional 3D-printed gearbox, which had to be made because the purchased gearbox did not arrive in time. This also showcases some of the flexibility that is added to additive manufacturing.

From idea into production

In the case of the heatsink press, which was requested by a customer, we have perhaps the best example of how a product goes from idea to production using the previously discussed concepts. It started with a particular requirement to press a heatsink onto an adhesive tape and heat it up so that the glue would melt, fastening the heatsink to the circuit board.

The project started with only technical specifications from the customer. Only three months had passed since the first version of the product was set up in production. This includes coming up with an idea, mechanical design in CAD, manufacturing and procurement of parts, assembly and programming. Without 3D-printing, it would be possible to create a functional machine in this relatively short time. Most of the development time was saved in 3D-printing because of fastening elements, such as the mounting brackets for different parts. Otherwise, it would have to be made using machining techniques, which would have delayed the project.

Some of the printed parts were used in high stress and high-temperature areas and would need replacement later. However, the initial parts were used. The customer first evaluated the machine for the first few production batches. When the first round of production was finished, the device was inspected more thoroughly. Appropriate changes were made, such as replacing printed parts with more substantial, machined parts where it was deemed necessary. By solving it this way, we could develop the machine without causing delays to the production, ensuring customer satisfaction.

Additive manufacturing has had a significant impact on meeting both internal- and customer requirements when it comes to custom solutions. It has also allowed us to investigate new, exciting ideas and research where it would otherwise be unavailable due to cost. Most importantly, it enables us to leverage our engineer's competence and creativity to meet our customers' ambitions.