Quality in electronics manufacturing is assured in many different ways. Personnel training, checklists, and instructions are the common ways to ensure that all produced products are flawless.

However, additional, and more sophisticated quality assurance methods are used to eliminate/reduce human error factors. One of those methods is electrical tests. As a rule, electrical tests require specialized test equipment that often needs to be developed for each project individually. This is where Kitron's test development services come into play for our customer’s products.

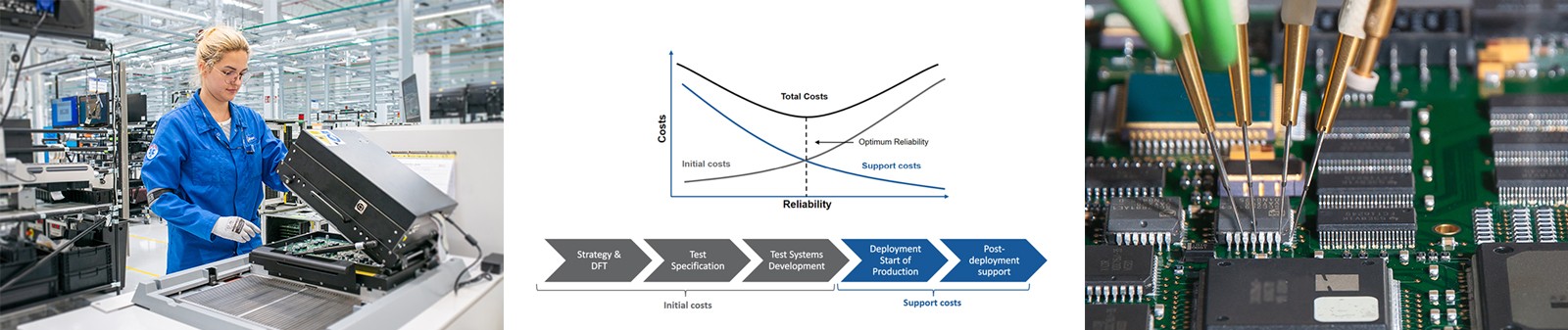

Production testing seeks to identify potentially defective products as early in their lifecycles as possible because the cost of reworking a defective product rises exponentially as a function of the time it takes for identification.

All starts with a test strategy

Test strategy defines what tests will be done on the product and overall test coverage. Each product might have a different test strategy based on many different aspects: the product's field of application, other quality procedures in the manufacturing processes, and error impact for the end user.

After the test strategy is defined, test specifications can be created to define the requirements for each test. The test specification is an essential document that describes the exact requirements and steps that need to be performed during the test with acceptable limits and results. Basically, it defines product acceptance criteria – if all requirements listed in the test specification are fulfilled, the product is accepted by the customer.

Kitron test development engineers are ready to analyze test specifications and design the best equipment that will fulfill all technical requirements a customer needs.

Covering a wide range of customer needs

Another aspect that Kitron's test development is proud of is its extended equipment lifetime. This mostly comes from the Medical and Defence/Aerospace sectors, where a customer’s product lifetime of 20+ years is not something extraordinary. Test equipment needs to be functional and ready for production throughout that period.

Equipment reliability comes with costs, and that is something we need to control throughout all equipment lifetimes. Support costs can become extremely high if the wrong technical solutions are selected during the project's design phase. It's complicated to replace or repair equipment that was [PM1] designed without a high focus on maintainability. It uses instruments and parts that are long out of stock and difficult to replace. Kitron learned this lesson through the long years of expertise in development and always creates a balance between product costs and reliability.

The key to success

Kitron develops state-of-the-art test systems for automated testing in production. Over the last 30 years, the department has worked on a wide range of projects within the following sectors: Connectivity, Electrification, Industry, Medical devices, and Defence/Aerospace. We continuously update the test methods available in the market while at the same time endeavouring to advance the development of testing and test philosophy for our customer’s needs.

Moreover, Kitron is a key member of the Nordic Test Forum (NTF), giving us access to leading international experts in the field. Certainly, we work hand-in-hand with our customers to get the best possible results in test strategy. Each project is allocated a dedicated technical project manager and a professional team of experts. To conclude, the key to creating a successful test strategy is conducting each project following Kitron's project model and in close cooperation with our customers.

Summary

Kitron creates custom test strategies to ensure our customer‘s products are fully functional before they are delivered further. Our engineers have mastered the art of designing a functional test that meets our customer‘s product requirements. Because without fully testing the product, how can anyone be sure it will work as intended?

Kitron has been a solid, long-term partner in electronics for years, typically manufacturing and delivering anything from fully assembled electronic circuit boards to complete end products for customers globally. The services and technology we offer are a result of our 60 years' experience. Test development is only one of the many key competencies offered by Kitron.