When talking about efficiency, we may think only about the system or simply an operator working faster. However, the efficiency of the testing process is a much more complex challenge.

To accelerate performance, the team of test engineers from Kitron Lithuania had to re-think and change the process and workplace of different test systems and reduce the testing area size. Thanks to our professional team's creative and strategic thinking, the challenge was successfully solved.

First steps of the project

As the company grows, we get more and more test systems that are not always compact or movable. Inefficient production floor space is a real challenge for every process engineer that has to work in this kind of workspace.

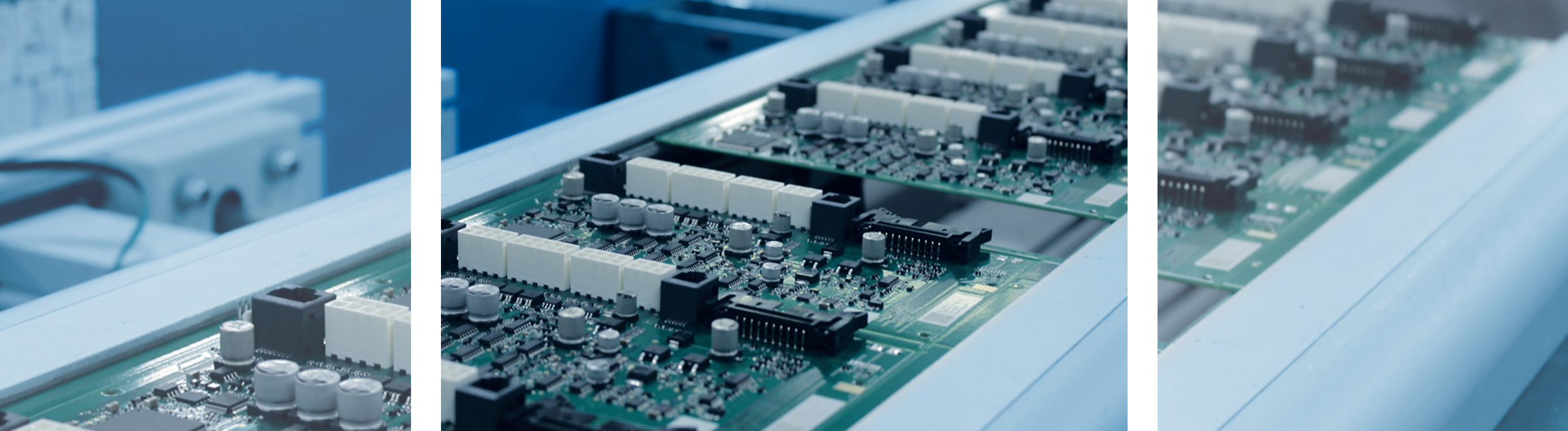

Typically, there are more than 300 different test systems with various production loads deployed on the manufacturing floor. Therefore, our target was to find ways to standardize these systems and find a simple but smart way to increase the efficiency of the test area.

In the project's first steps, automatic storage systems were discussed, but all these automatic systems are expensive and difficult to install. Hence, another way had to be found. The goal remained the same – how to save as much space as possible and increase efficiency.

The turning point of the project happened when engineers understood that they needed to have two different test systems standards - for high and low runners products.

The solution

It was decided to split all test systems into two types:

- Low runners - 1000h/year or lower in test operation.

- High runners - 1000h/year or higher in test operation.

For the low runners, a new storage standard was created. With this new concept, the idea was to utilize the available production room height instead of its area and thus save the factory floor. The concept consists of:

- 6 shelves rack with 30 tabletops as removable shelves.

- Semi-electric lift.

- 4 workplaces (special frames of a table).

The key idea developed by test engineers at Kitron Lithuania is that test systems should be deployed to specific tabletops. Those tabletops can then be stored in racks. Based on production demand, it is easy to take a specific tabletop with a test system from the rack and put it on the table frame for usage. All tabletops have standardized connectivity boxes with power and network connectors. These connectors let us minimize test system setup time in the workplace.

All 4 workplaces in the test area are next to each other, which makes it possible to combine test systems for a parallel test operation.

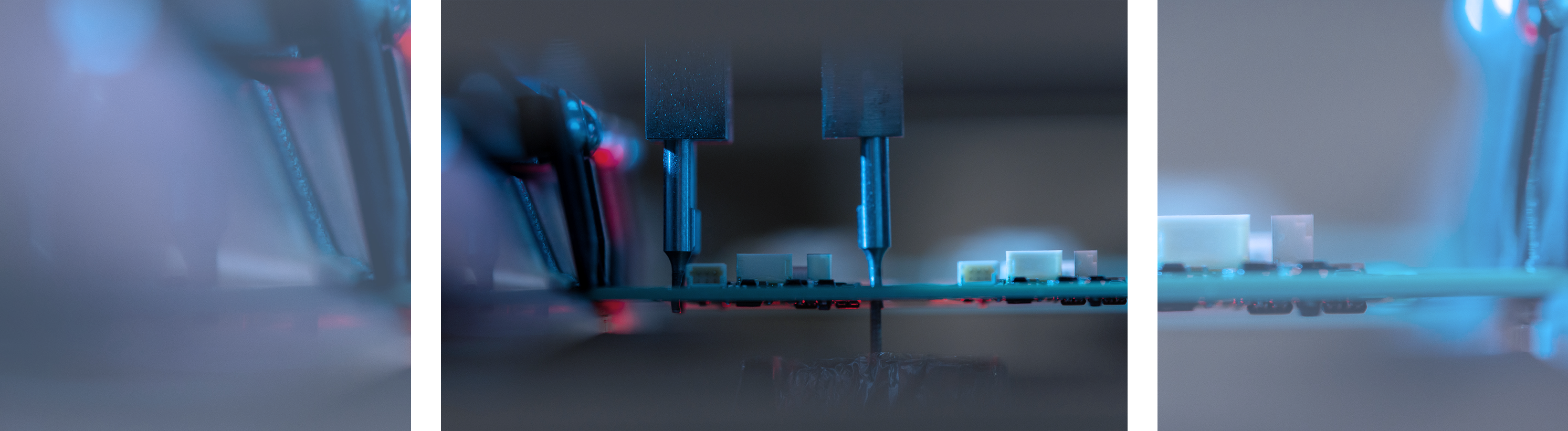

For the high runners, a movable test standard was developed with a special trolley concept. This trolley is movable and compatible with our local automatization team requirements in case the test system would be integrated with a robotic arm.

This standard makes the test system easy to move on the factory floor. A movable system allows the combining of two or more operators together.

A 60x60 cm dimension aluminum construction trolly is light and ergonomic. The trolly has two shelves where all the test equipment is placed. The top side is only serving as a test fixture.

Summary

With the new test storage standard, the team was able to save 100 square meters of manufacturing area already, and the ability to organize the test process in parallel is expected to save 5000h of test operation time annually.

This exciting achievement shows that electronics engineering is not just about working with schematics or debugging. Methods of test operation on the production floor are also a subject for review and improvement. In this case, the team led by Ignas Povilaitis significantly improved factory floor utilization and test operation efficiency. Furthermore, the developed concept can be easily copied to other Kitron factories bringing benefits corporate-wide. This was a result of team dedication, analytical thinking, and trying to find robust, out-of-the-box solutions.

“Our professional team is the key to succeeding in everyday challenges - we are proud of their achievements. We wanted to improve efficiency and productivity by implementing this project. In the end, improved operations are for our customer’s benefit. We are constantly working on developing different ideas, and I expect more of them are on the way.” - shared Mindaugas Sestokas, Managing Director of Kitron Lithuania.

We are proud that in this challenging period, we can find and implement such great solutions that allow making Kitron's processes more efficient and free-up production space. This is a new stage of the test process. After this project, our team showed that the best solutions should always be simple but smart.