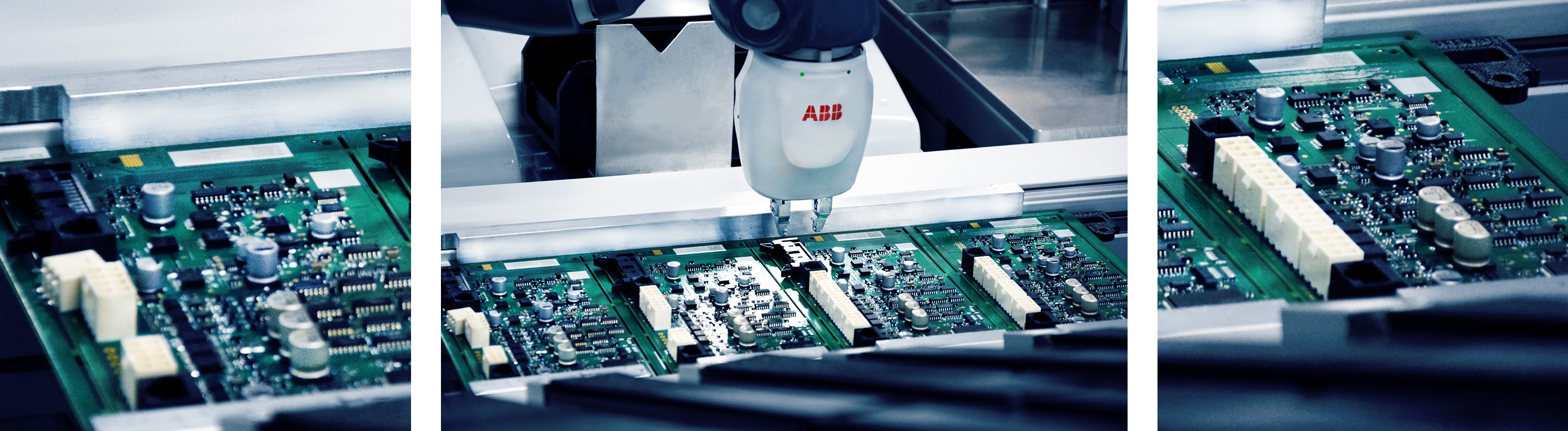

Robots have revolutionized manufacturing – at Kitron, we are already putting the future of robotics into place. However, the automation process is always a very challenging task, but the Automation Engineers at Kitron Lithuania have found their way to make it. The main focus was to make the low-value product testing more efficient and allow operators to work on more value-added, less routine tasks instead.

The robotic testing cell is the first Kitron's design solution for automating manual testing jigs. A unique design gives flexibility and makes the robotic cell universal for other product testing with minimal investment and short setup time.

Ensuring a reliable service

This collaborative technology is testing jigs from standard workbench to custom-designed rack and ensures testing jigs are available not only for automated processes but, if necessary, for manual as well. Because all measuring equipment is inside the custom-designed rack, it is possible to save more than 50% of the occupied area, eliminate potential risks and use the ergonomic movable solution of testing equipment for future projects.

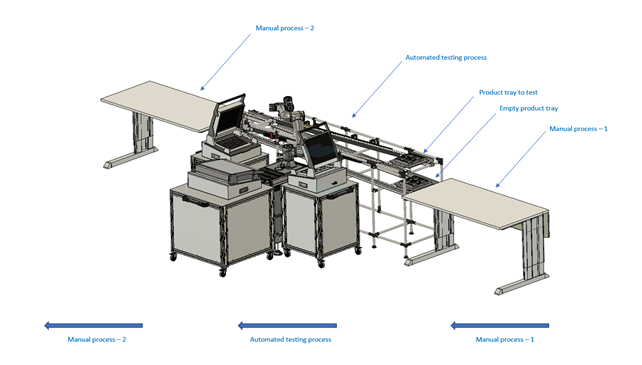

When it comes to the design of the robotic cell – flexibility is the aim. Therefore, the Automation Team came up with a smart "rack slot" solution.

The robotic cell layout has three rack slots in front, on its right and left sides. These rack slots are universal and can be used for other product test equipment. The changing process is quick and accurate because of the fast opener's attachment to manual test jigs. The cell has an HMI screen where the operator chooses the program according to the product, inserts test equipment, and the process starts.

The new robotic cell is designed following all the safety standards to protect both people and the products.

The cell itself has five main doors, which are equipped with special sensors. For example, if any of the doors open during the process, the robot simply stops functioning. Once the doors are closed, the process continues. Also, if the special service doors open, the robot immediately drops to low speed. Another important aspect is the sound reduction – this makes it comfortable for operators to work.

How does it work?

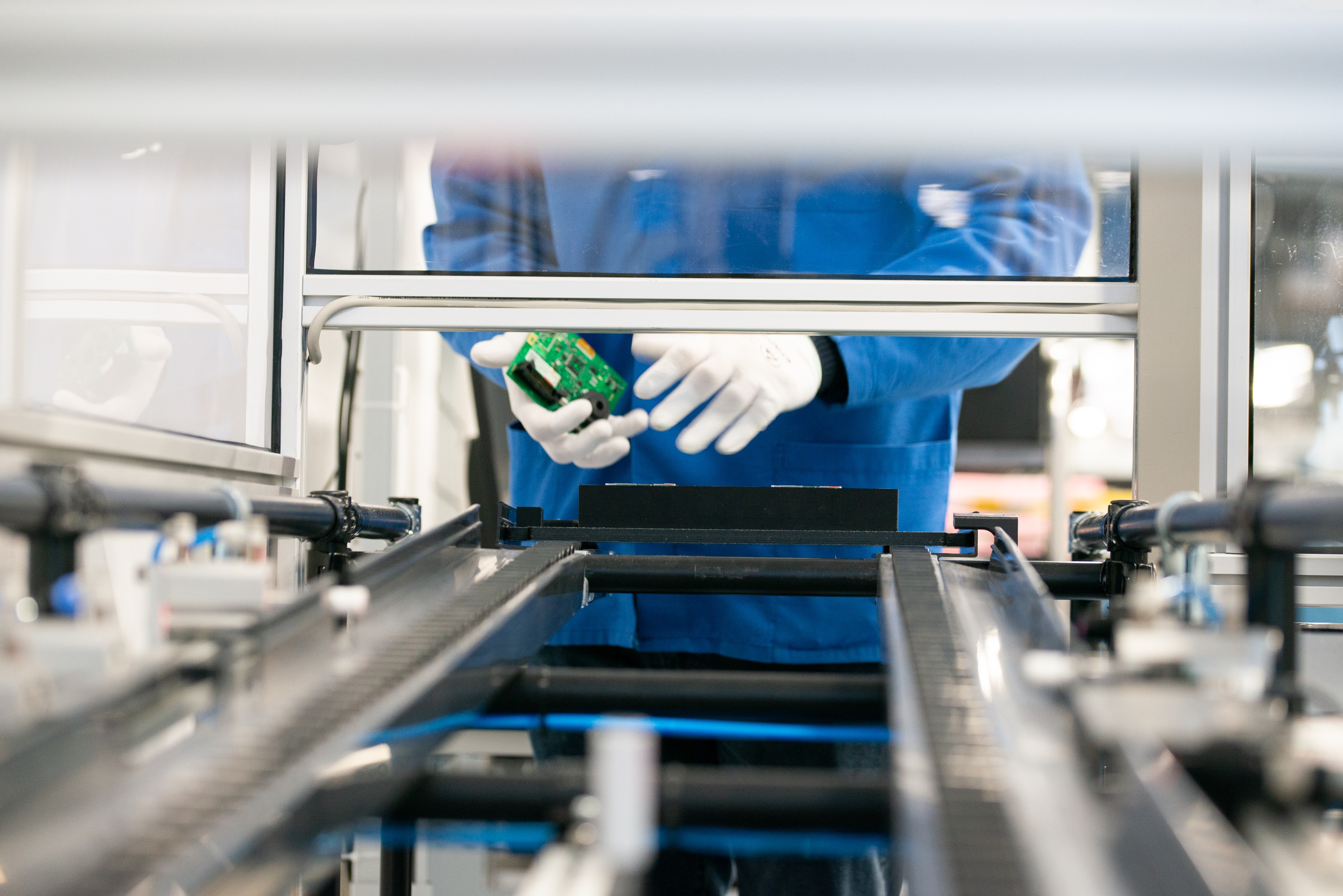

Today the robotic cell works in-line method between two manual processes.

The first manual process is when the operator, after finishing his job, inserts the products into a specially designed transporting tray. The engineers have designed the trays following the poka-yoke method and eliminated potential mistakes to insert the product incorrectly. The fully loaded tray travels by a gravity conveyor to the picking position. That is when the robot picks the products and inserts them into the testing equipment. After the test is finished, the robot separates the products as passed and failed ones.

Passed test products are placed into the same product tray where it was picked. The failed products are placed into a separate dedicated tray in front of the cell. After the product testing process is finished, the tray travels to the last manual process. The operator picks the products and pushes a button to return the tray back to the first manual process.

Kitron’s vision: industrial automation is the way forward

Creating a flexible and efficient solution at Kitron Lithuania was only the starting point. There are other tasks the Automation Engineers has for the future - they intend to duplicate this solution in a few other Kitron’s manufacturing facilities. The knowledge and experience they have gained until now will make it possible.

Also, by automating manual processes, the employees will be directed to other areas of production, which will make their work more interesting and dynamic.

Even with the constant automation solutions taking place, the need for human resources at Kitron is not expected to decrease. Even the opposite - since the customer base and, in parallel, the orders are constantly growing, so is our team!

.png)