Modern electronics manufacturing has embraced automation, and there's no doubt that it's going to play an increasingly significant role in the future. The professional automation team at BB Electronics in India now lets Kitron offer even more competitive services to our customers. With the increased demand for automation at Kitron Group, a centralized service provides the same level of expertise across all factories.

BB Electronics is located in Chennai, India, which is a major center for the automobile, software development, hardware manufacturing, and healthcare industries. In Chennai, there is a strong environment for engineering and technology education that has contributed to the growth of the electronics industry.

The role of people and competencies in the automation process is critical. We have a group of experienced engineers in industrial automation and robotics on our Global Automation team.

High-performance products require precise automation solutions. The future is smart, and we are excited to lead it!

A variety of applications

The innovative solutions we offer are created by a team of highly skilled automation engineers who combine dedication, creativity, and knowledge of manufacturing. Our automation team thrives on the opportunity to meet the challenges of material handling, assembly line automation, testing and inspection, palletizing, milling and drilling operations, and turnkey automation, which includes end-to-end solutions.

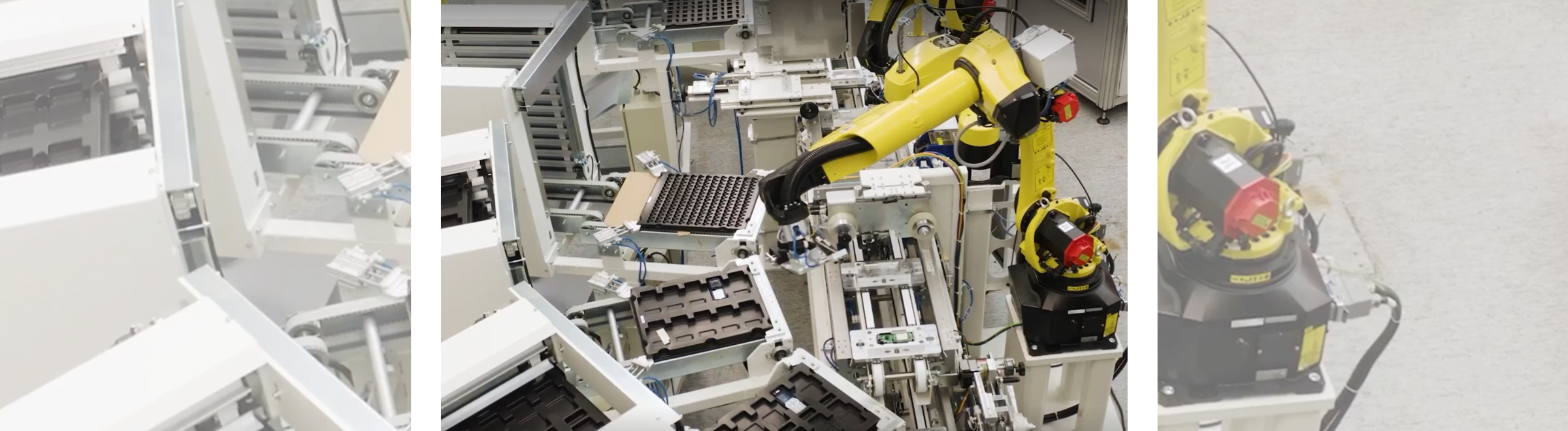

Robotic automation offers the capability of addressing a wide range of material handling challenges. This means robots with specialized grippers are installed to move products from one location to another with high speed and accuracy. The robots can be integrated with existing equipment, such as conveyors and other workstations. These solutions are beneficial to industrial environments since they reduce the amount of tedious work that must be performed.

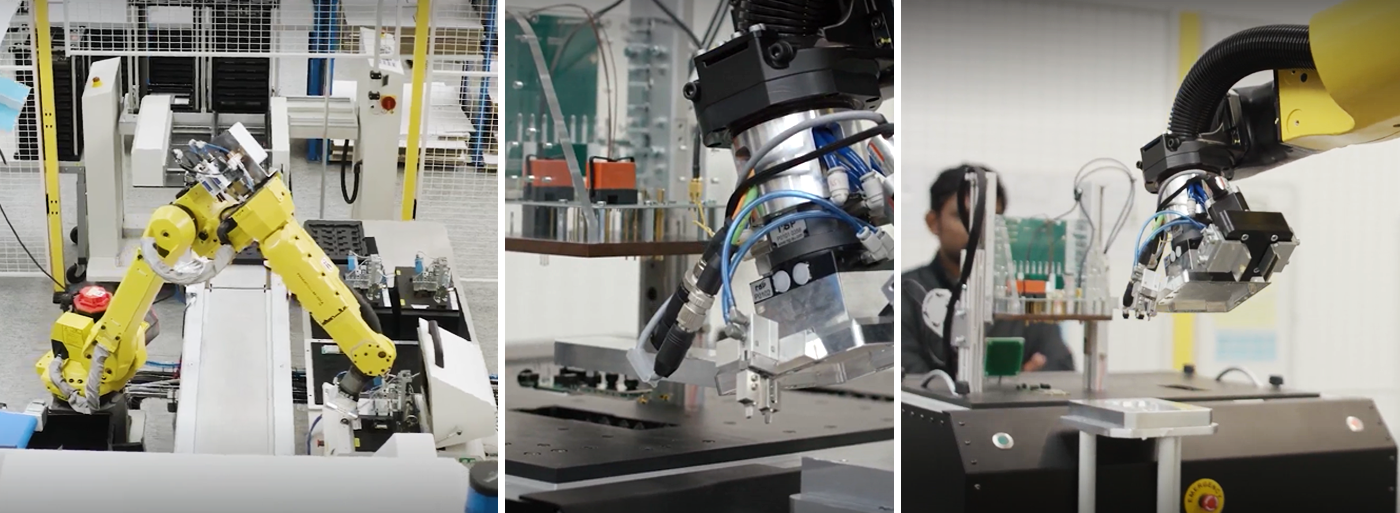

When it comes to assembly line automation, processes that previously employed conventional methods are replaced with custom-designed robotic cells. With extensive experience implementing automation facilities wherever necessary, BB Electronics' automation team in India knows how to improve safety, quality, cost, delivery, and the environment. Complex and repetitive procedures can be automated by robotic systems, leading to an increase in efficiency and a reduction in cycle times.

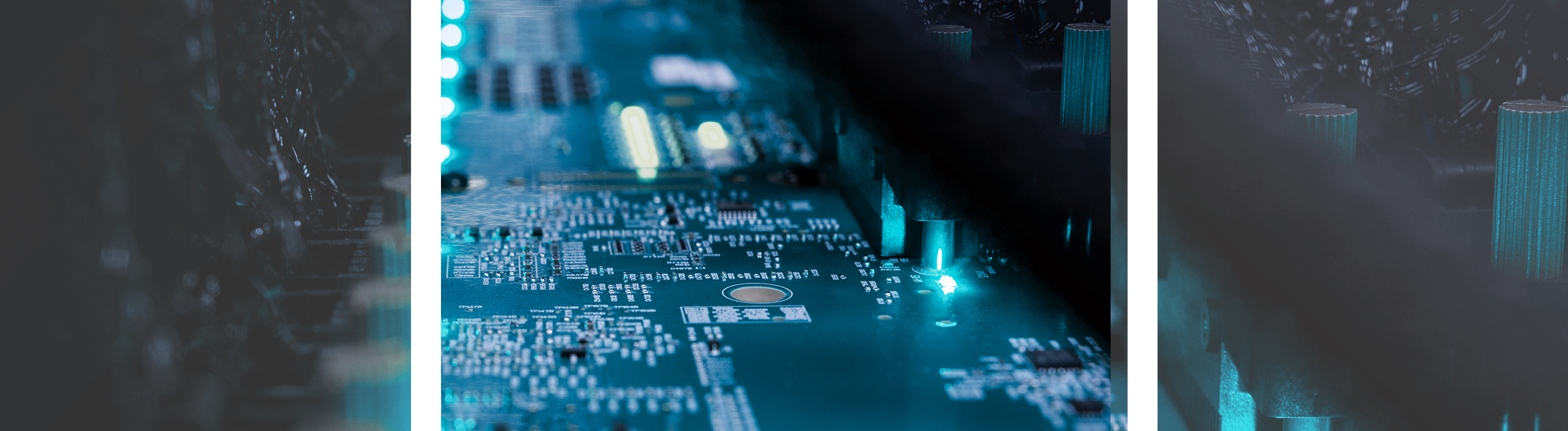

Our customers' products come with very little room for error, so testing and inspection are at the core of what we do. Testing devices based on PCs and PLCs are used to develop specialized automated testing cells for pre-product or final-product validation processes. It uses 2D and 3D vision systems integrated with automated cells to control products and production processes. In addition, the automation team designs and develops cells that integrate customer testing systems.

Another process, palletizing, has some big challenges: pattern flexibility and cycle time. However, these challenges are efficiently tackled by custom-designed robotic systems. Our automation team partners with major robot manufacturers to select specialized robots that can handle heavy payloads and work at high speeds. The robot software is designed in such a way that allows the user to control patterns and the status of procedures easily.

Moreover, robots score highly for repetitive and precise tasks. When it comes to sealing and dispensing procedures, robots that follow a specific path accurately and dispense specific substances uniformly are an asset. In such cases, robots are programmed to interface with material pumps, regulators, and more, in order to produce specific parts. Automated dispensing systems of high quality are integrated with the robots to meet the demands of sealing and dispensing process. The robot software is developed to interface with a wide range of equipment and is also user-friendly.

Additionally, robots can be used to automate specialized PCBA routing and soldering operations. Fully automatic milling cells are designed and developed for the de-paneling of PCBA’s. It works with automated feeders and a milling machine integrated into the robot for feeding and delivering the de-paneled PCBAs after milling. Specialized soldering requirements are achieved through automated cells where a robot handles the alignment of the PCBA’s which need high level interconnection in addition to handling the soldering process with an automated feeding system.

Last but not least, turnkey automation includes end-to-end solutions that are required for a complete process flow. The automation team at BB Electronics India has developed and conceptualized a complete turnkey solution for special processes and product assembly. Turnkey solutions are designed, built, supplied, and installed so that the operator only needs to press the key to operate.

BB Electronics automation team engages with customers in the early design phase to analyze the products towards Design for Automated Assembly (DFAA) and supports customers in the possibility of optimizing the design so that the product is suitable for automated assembly in terms of material handling, part selection and ease of assembly. By partnering with customers, the automation team at BB Electronics provides expertise and solutions for process optimization, cost-effectiveness, and overall product quality improvements.

Summary

Applying the latest knowledge and technologies in automation enables us to build our customers' products faster and support successful manufacturing strategies with lower production costs and higher productivity.

The automation team at BB Electronics India employs only leading technological practices. We offer a wide range of automation solutions and are dedicated to finding reliable and sustainable solutions. Utilizing our business and industry expertise, we deliver exceptional ROI.