In modern electronics manufacturing, the limitations of traditional manual inspections, such as inefficiency, inaccuracy, and high costs, are becoming increasingly evident.

At Kitron Malaysia, we are accelerating visual-inspection automation through mini AOIs and a layered system design. As part of this effort, we introduced an Automated Visual Inspection System featuring a robot-arm-based inspection capability that can perform both visual and physical checks on finished products, ensuring high-quality standards.

The system was developed by Kitron’s engineering team in China and Malaysia, leveraging their years of expertise in electronics assembly and quality control, and tailored specifically to meet the inspection needs of finished products at Kitron Malaysia.

Efficient Alternative to Manual Inspection for Finished Products

Due to traditional visual inspection's heavy reliance on work experience, human inspectors often miss critical angles or details. The Automated Visual Inspection System detects quality issues during the assembly process, including missing or damaged parts, reversed labels, and non-compliance with barcode rules, especially in finished product assemblies where errors can impact the final product delivered to customers.

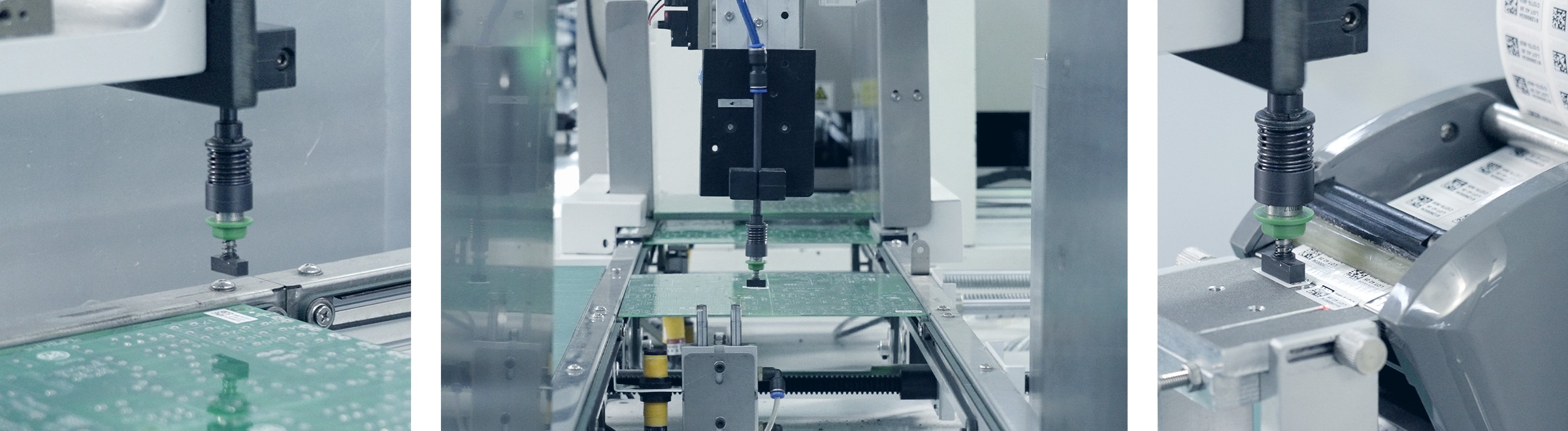

The system uses a robotic arm and a 360° fixture servo rotation system to visually inspect all necessary angles without blind spots based on finished product characteristics.

The Automated Visual Inspection System is equipped with a 20-megapixel camera and two light source controllers, which can detect and measure the size of the majority of components and features on the assembly.

Operators require minimal training to use the system effectively and can operate it independently. When a defect is detected, the system automatically triggers an alarm and highlights the issue, eliminating the need for manual intervention.

Flexible Solution for Further Application

Switching between fixtures and programs allows the system to be used for different types of product inspections, making it a flexible and highly efficient solution for the electronics manufacturing process.

The system integrates multiple advanced technologies, including a PLC, a 6-axis robotic arm, a quick-switching fixture mechanism, a 360° servo flipping fixture, and a high-resolution visual inspection system.

Rapid tooling changes maintain installation accuracy and allow quick model changeovers. The PLC also reserves capacity for future products and additional inspection content.

Whether it is PCBA, sheet metal parts, precision hardware, or plastic products, the equipment can be quickly adapted to the inspection needs of different sizes, semi-finished products, and finished products through PLC program switching and visual template updates.

.jpg)

How does it work?

Once the device is set up with the right program and fixture, the inspection process requires minimal effort. Products are placed in the fixture and inspected automatically with a single button press.

The robotic arm and PLC work together to carry out inspections with precision. The Automated Visual Inspection System evaluates each product and provides instant feedback. Qualified units proceed automatically, while defects trigger alerts for immediate operator attention.

The system stores inspection photos and records tied to each product’s serial number for added reliability. This ensures full traceability, making quality control both efficient and transparent for Kitron Malaysia.

Summary

As part of our ongoing drive at Kitron Malaysia to expand and modernise visual-inspection automation, we continue to integrate advanced solutions that strengthen both capability and consistency across production.

The Automated Visual Inspection System delivers flexible, multi-product inspection, from PCBA to plastic and metal components, with high precision and reliability. By reducing human error and shifting from manual checks to automated processes, the system significantly boosts accuracy and efficiency.

Developed specifically for Malaysia and built through close collaboration between the Kitron China and Kitron Malaysia teams, this solution enhances operational quality, efficiency, and overall performance for customers across the region.