With the ongoing advancements in manufacturing technology, traditional 2D barcode labels have been replaced by laser barcode labels. Nevertheless, certain products still require paper labels due to specific customer or regulatory requirements, making it impossible to switch entirely to laser labelling.

To address this challenge, Kitron China’s engineering team has developed an efficient automated labelling solution to replace the manual process.

Low-Cost, High-Efficiency Solution

Automated labelling solutions are already widely used across the EMS industry. Labels are typically applied to surface-mount technology (SMT) machines. However, such high-investment systems are usually designed for high-volume production, making them unsuitable for Kitron China’s high-mix, low-volume operations in Suzhou.

To solve this, Kitron China engineers leveraged existing in-house equipment to design and build a customised low-cost automated labelling line that perfectly fits our production environment.

The automated labelling line minimises manual labour, optimises pick-and-place speed with customised nozzles, and allows continuous operation with minimal downtime.

The line fully utilises equipment already available on-site, eliminating the need for expensive new machinery. Rather than large investments, it delivers an efficient and practical solution developed through the skills and expertise of Kitron China’s engineering team.

How it Works

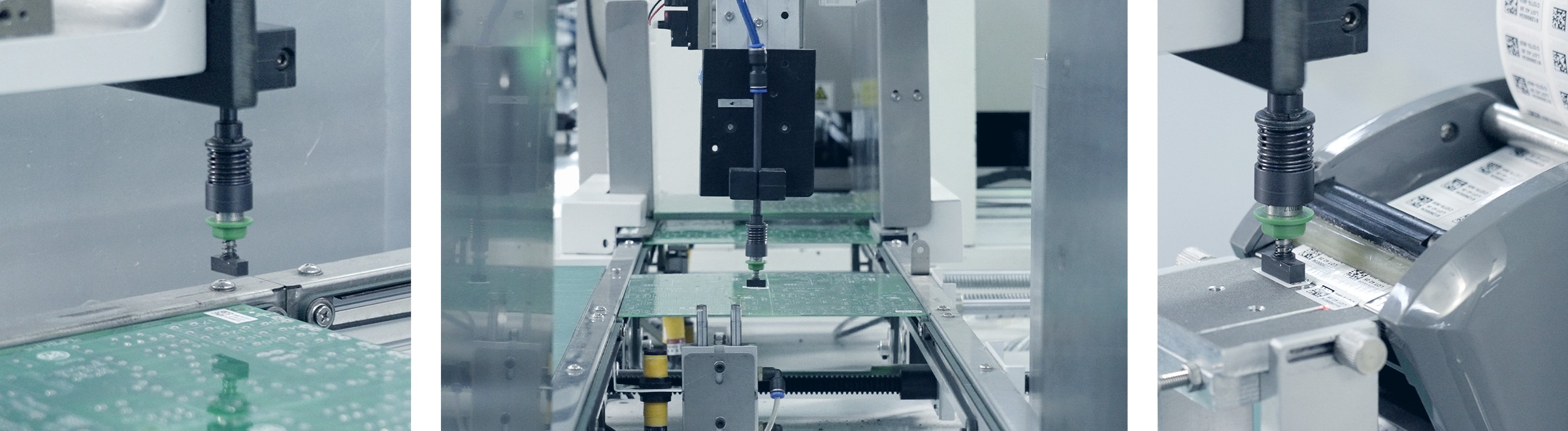

The line is composed of a loader, an unloader, a PCB hold conveyor, label feeders, and Fanuc SCARA robots.

Engineers developed a custom control box to manage the entire system, ensuring seamless coordination. Nozzles were designed to accommodate various label types and sizes to achieve the highest pick-and-place rate.

The process is fully automated: the operator simply places the printed circuit board (PCB) on the loader, selects the appropriate program, and starts the process. From there, the system automatically transfers PCBs, picks up and applies labels, and unloads the completed PCBs. The entire process runs without additional manual intervention, resulting in higher productivity, consistent quality, and improved process reliability.

Summary

The automated labelling line developed by Kitron China represents far more than a replacement for manual work; it is a demonstration of engineering innovation, smart investment, and resource management.

This in-house development approach maximises the value of existing equipment, reduces costs, enhances process stability, and ensures consistent quality.

Kitron China’s commitment to continuous improvement and cost-effective automation delivers our customers greater efficiency, reliability, and value.