The key to success in electronics manufacturing is efficiency and precision. Automated Through-Hole Technology (THT) machines have revolutionized the electronics manufacturing process. These advanced machines have significantly enhanced efficiency and accuracy, making them an integral part of the manufacturing line.

How does THT work?

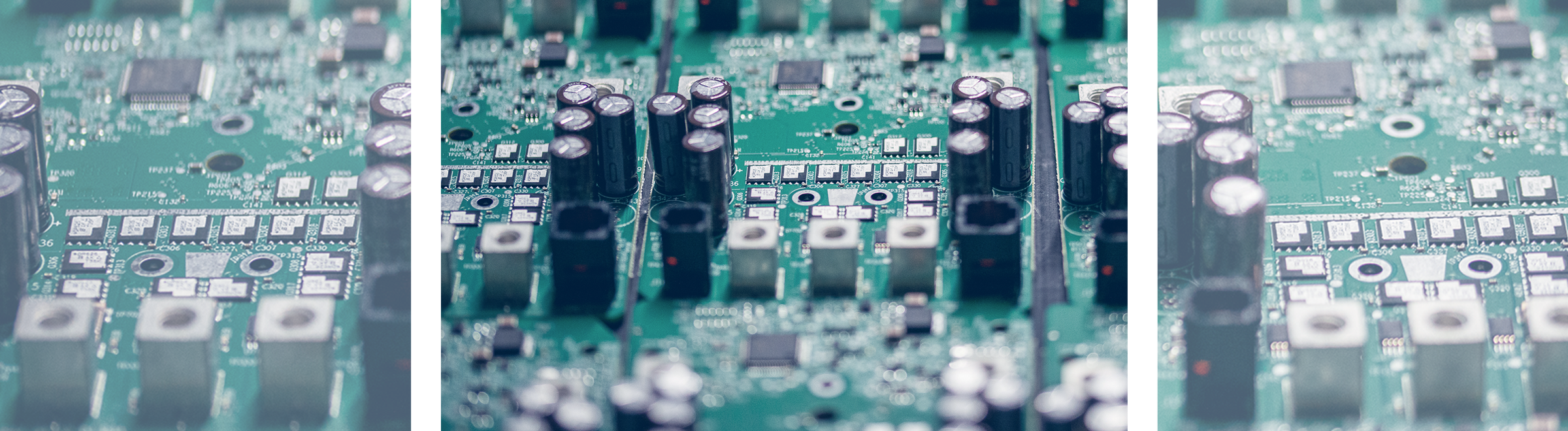

Through-hole technology (THT) is a traditional method of electronic component assembly where the leads of components are inserted into holes on a printed circuit board (PCB). This method has been widely used for decades and is known for its reliability and durability. For components like connectors and transformers that will be subjected to mechanical and environmental stress as well as high heat, THT is the perfect choice. However, THT assembly is a labor-intensive process when done manually. Automated THT inserters are now available to speed-up the process, making it faster and more accurate than manual assembly.

Automated THT: The Game-changer

THT machines are designed to automate the insertion of electronic components into printed circuit boards (PCBs). In traditional manual assembly, technicians would manually insert the components using soldering equipment. This process was time-consuming and labor-intensive.

With the introduction of automated THT machines, Kitron has been able to streamline the assembly process. Automation eliminates the need for manual intervention, reducing the chances of error and increasing productivity.

One of the key advantages of automated THT machines is their ability to handle a wide range of component sizes. These machines are equipped with specified grippers, allowing them to accommodate various component dimensions. This flexibility enables Kitron to manufacture PCBs for different industries, especially Electrification. In addition, with the addition of a selective soldering machine in the same line as the THT machines, the board can be completed much more quickly as it is both assembled and soldered when it comes out of the line.

Furthermore, automated THT machines at Kitron are equipped with advanced vision systems. These systems use cameras to inspect the components before placement, ensuring their correct orientation and alignment. This quality control feature minimizes the risk of faulty assemblies and helps maintain the high standards that Kitron is known for.

In addition to their precision and efficiency, automated THT machines also offer cost savings. By reducing the need for manual labor, Kitron can optimize its workforce and allocate resources more effectively. Moreover, the machines' high throughput enables faster production cycles, resulting in shorter lead times and improved customer satisfaction.

THT automated inserters can handle a wide variety of through-hole components, including resistors, capacitors, connectors, and switches. It is possible to program them to accommodate a variety of component sizes and shapes.

The integration of automated THT machines into Kitron's electronics manufacturing process has had a significant impact on the company's overall operations. The machines have not only improved efficiency but also enhanced the quality and reliability of the manufactured electronics products.

By leveraging their capabilities, Kitron has been able to deliver high-quality PCB assemblies to a diverse range of industries. The adoption of automated THT machines highlights Kitron's commitment to innovation and excellence in electronics manufacturing.

Summary

THT automated inserters have revolutionized the electronics manufacturing industry by significantly improving assembly efficiency, precision, and consistency. In a rapidly evolving tech landscape, where speed and quality are crucial, these machines are indispensable tools for manufacturers looking to stay competitive.

As technology continues to advance, THT automated inserters will likely evolve as well. This will contribute to the ever-growing demand for high-quality electronic devices. In a world that relies on electronics, Automated THT plays a crucial role in ensuring the reliability of the products we use every day.