Kitron is constantly seeking innovative automation solutions to help our customers achieve higher quality and greater reliability in our processes and products. Rather than just developing machines, Kitron is following a long-term roadmap toward a modular automation platform that can be scaled and reused across processes and sites.

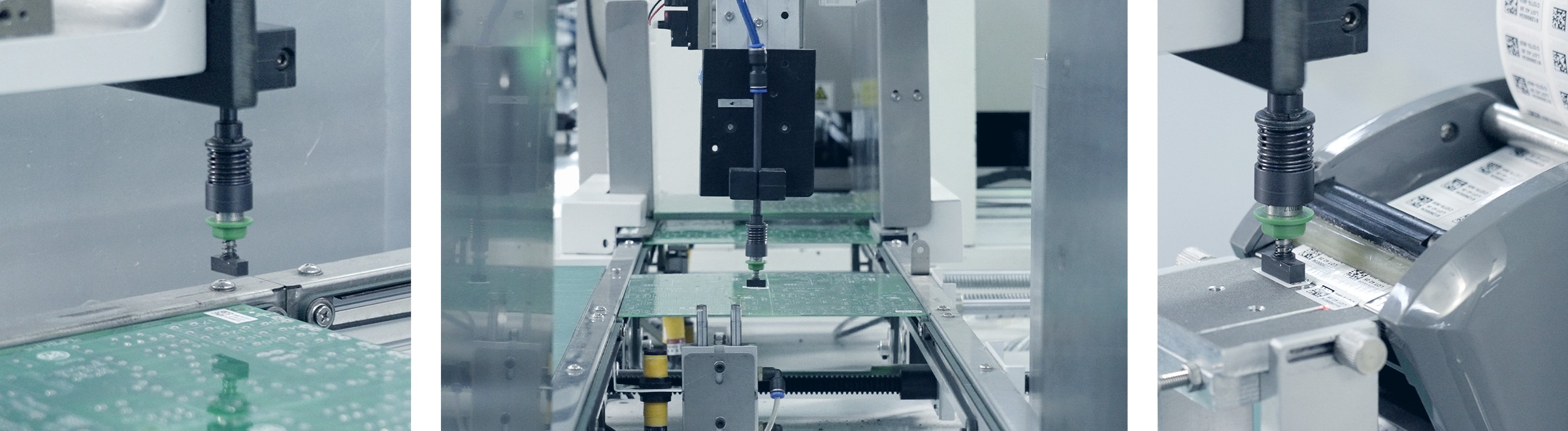

The latest solution introduced by the Kitron Global Automation team is the improved Depaneling Machine Version 2, which helps deliver higher product quality and reduce costs in electronics manufacturing.

Upgraded Version

Depaneling Machine Version 2 is a major upgrade in Kitron’s Standard Machine Series. This series is designed to automate key electronics manufacturing services (EMS) processes, such as depaneling, dispensing, screwing, soldering, and laser marking, all tailored to meet our production and customers' needs.

Our journey to create the Standard Machine Series began with a simple idea: to build smarter, more adaptable machines that support our work in a low-volume, high-mix production environment.

This approach does not aim to reinvent existing technologies, but to integrate them into a standardised, modular platform that fits Kitron’s specific production model.

Depaneling Machine Version 1 was developed and implemented earlier. The trial helped us identify key improvement areas, particularly in ESD protection, usability, design, and software setup.

Version 2 is a significant upgrade that incorporates feedback from Version 1, delivering one of the most efficient and compact depaneling solutions available today. It also strengthens the underlying platform we will use for future modular automation cells.

.jpg)

How does it work?

The Depaneling Machine is designed to make depaneling faster, safer, and more accurate while ensuring consistent quality and reducing operator effort. It is also flexible and supports both router and saw-cutting operations.

Some key features include:

- Dual-Fixture Axis: Operates in a swapping motion. While one fixture is working, the other is being prepared, reducing idle time and enabling continuous operation in a compact space.

- Automatic Tool Change: Minimizes downtime, improves precision, and boosts efficiency. The system also uses a contactless sensor to check bit diameter for accuracy.

- 5-Stage Bit Depth Control: Ensures stable, precise cutting with extended tool life and superior edge quality.

- Simplified Software: A single program handles everything, including MES connectivity for traceable data, camera-based teaching, and automatic tool calibration.

- Enhanced Safety & Maintenance: Features include improved dust collection, an ioniser for ESD control, door safety switches, and a light curtain for operator protection.

This approach ensures that each new machine strengthens the overall system, creating long-term scalability and efficiency improvements for Kitron and our customers.

Summary

This solution represents one step in a broader journey toward modular automation design, an approach that builds on existing technologies and adapts them into a flexible, standardised platform for current and future manufacturing needs.

By doing so, Kitron continues to build a foundation for smarter, more unified automation solutions that deliver long-term value, consistency, and trust to every customer we serve.